Author: Admin

Date: Apr 26, 2025

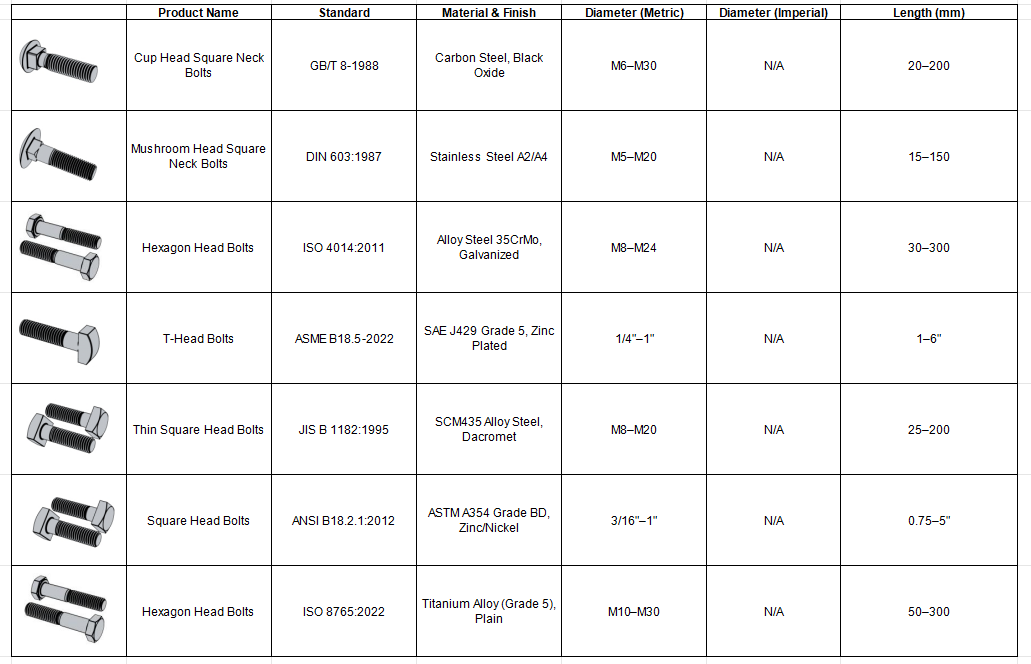

Automotive Bolts: High Strength Steel, Stainless Steel & Titanium for EV & Chassis Applications (DIN, ISO, GB, ASME)

Key Features & Automotive Applications

-

GB/T 8-1988 (China):

- Widely used in commercial vehicle chassis for M6–M30 connections.

- Black oxide finish provides basic corrosion resistance (salt spray 72h).

-

DIN 603:1987 (Germany):

- Stainless steel (A2/A4) variants prevent rust in EV battery pack assemblies.

-

ASME B18.5-2022 (USA):

- SAE Grade 5 material (≥120 ksi tensile strength) for heavy-duty truck suspensions.

-

JIS B 1182:1995 (Japan):

- Dacromet-coated alloy steel bolts for coastal climate applications (salt spray 480h+).

-

ISO 8765:2022 (Global):

- Titanium alloy reduces weight by 40% vs. steel, ideal for EV lightweighting.

Industry Recommendations

- EV Battery Frames:

- Use ISO 8765 titanium bolts for weight reduction and corrosion resistance.

- Chassis Connections:

- Prioritize DIN 603 stainless steel or JIS B 1182 Dacromet-coated bolts.

- Aftermarket Repairs:

- GB/T 8-1988 black oxide bolts offer cost-effective solutions for non-critical parts.

For full technical drawings and compliance certificates, refer to official standards from DIN or SAE.

Contact Our Experts

And Get A Free Consultation!

And Get A Free Consultation!

English

English 中文简体

中文简体