Automotive Supply Chain Insights: Automotive Chassis Fastener Applications, Important Facts You Need to Know & Selection Guide

The automotive chassis is the vehicle's foundation, supporting the entire body and bearing various loads from the engine, suspension, and wheels. The reliability and safety of the chassis are paramount, and fasteners play a crucial role in ensuring the reliable connection of its components. Compared to body and interior fasteners, chassis fasteners must withstand greater loads, impact, and vibration, and typically operate in more demanding environments.

Common fastening methods in the automotive chassis include:

Bolted connections : This is the most common connection method in the chassis, using bolts and nuts to connect various chassis components, such as those in the suspension, steering, and braking systems. Bolted connections provide high strength and reliability and are easy to disassemble and maintain.

Screw connections : Screws are typically used to connect auxiliary components in the chassis, such as sensor brackets and pipe clamps. Screw connections can provide sufficient connection strength and are easy to install.

Riveting : Riveting is relatively less common in the chassis and is mainly used to connect thin-plate components, such as the connection between the body and the chassis. Riveting can provide high connection strength but is not easy to disassemble.

Welding : Welding is a common connection method in the chassis, primarily used to connect the frame, suspension control arms, and other major load-bearing components. Welded connections offer the highest connection strength and rigidity but are not easy to disassemble and maintain, and the welding process requires high precision.

Self-piercing riveting (SPR) : Self-piercing riveting is a new type of connection technology that combines the advantages of riveting and stamping. It can be used to connect thin-plate components made of different materials, such as aluminum alloys and steel plates. Self-piercing riveting is increasingly used in automotive chassis, especially in the field of new energy vehicles.

Performance Parameter Requirements

Automotive chassis fasteners have very stringent performance parameter requirements, primarily including:

Strength : Chassis fasteners must withstand various loads from the vehicle, including static, dynamic, and impact loads. For example, suspension system connecting bolts must withstand the impact loads transmitted by the wheels, and braking system connecting bolts must withstand the enormous inertial forces generated during braking. Therefore, the strength grades of chassis fasteners are typically required to be above grade 8.8, and even reach grade 10.9 or 12.9.

Fatigue strength : Chassis fasteners are subjected to cyclic loads during vehicle operation, so they must have good fatigue strength. For example, suspension system connecting bolts constantly endure tensile-compressive cyclic loads during vehicle travel. Insufficient fatigue strength can easily lead to fatigue fracture.

Stiffness : The stiffness of chassis fasteners directly affects the vehicle's handling performance and ride comfort. Insufficient fastener stiffness can lead to loose or deformed connections, thereby affecting driving performance.

Corrosion resistance : Chassis fasteners typically operate in harsh environments, such as those with humidity, high temperatures, and salt spray. Therefore, they must possess excellent corrosion resistance.

Loosening resistance : Chassis fasteners are subjected to vibration, impact, and other forces during vehicle operation. Therefore, they must have good loosening resistance to prevent connection loosening.

Category Selection Guide

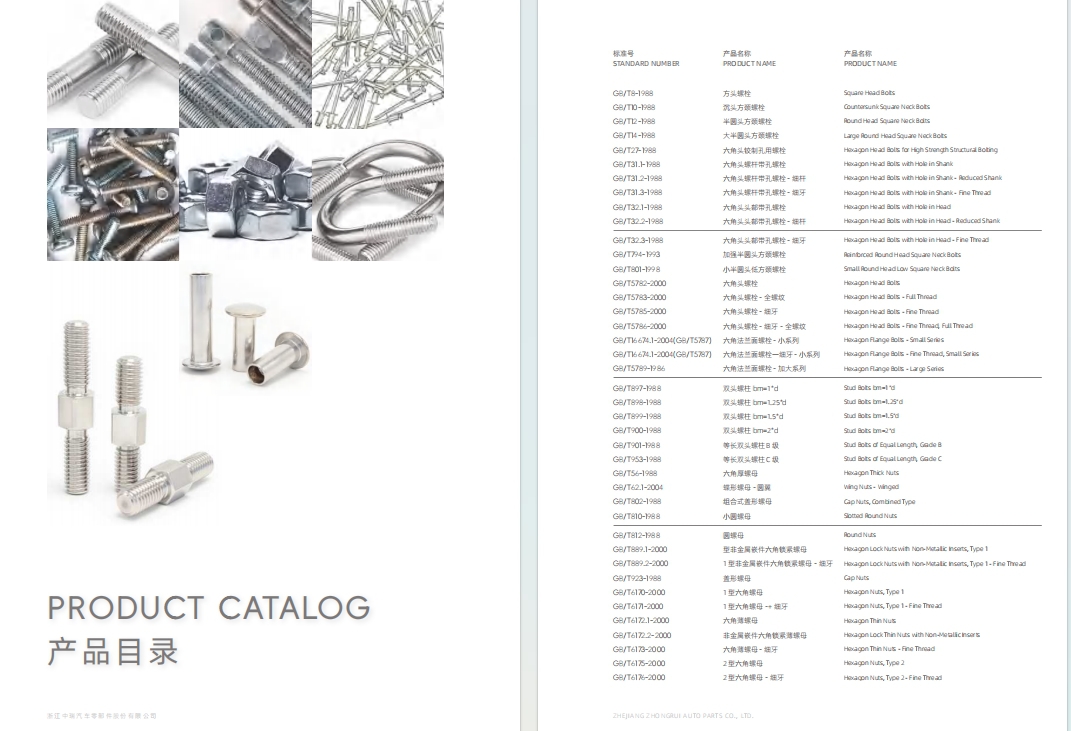

Automotive chassis fasteners come in a wide variety. The appropriate type should be selected based on the specific application and performance requirements. Here are some common chassis fastener categories and selection references:

Bolts :

Hex head bolts : These are the most common type of bolt in the chassis and are suitable for most connection scenarios. When selecting, choose the appropriate strength grade (e.g., 8.8, 10.9, 12.9) and size specifications based on the load.

Flange bolts : Flange bolts have a larger bearing area, which improves connection reliability. They are suitable for connecting thin-plate components or applications that require withstanding larger loads.

Wheel bolts : Wheel bolts are crucial components for connecting the wheels and the hub. They need to withstand significant tensile and shear forces.

Stud bolts : Stud bolts are mainly used for connections subjected to tension and shear forces. They are characterized by threads at both ends and a plain shank in the middle.

Nuts :

Hex nuts : Used in conjunction with hex head bolts, these are the most common type of nut.

Anti-loosening nuts : To prevent connection loosening, anti-loosening nuts, such as nylon insert lock nuts and all-metal self-locking nuts, can be used.

Flange nuts : Used in conjunction with flange bolts, these can improve connection reliability.

Cap nuts : Protect the bolt end, prevent rust and corrosion, and provide a more aesthetically pleasing appearance.

Screws :

Hex socket head screws : Suitable for applications with limited installation space, such as connecting brake calipers.

Self-tapping screws : Used to connect thin-plate components, such as connecting body covers.

Other fasteners :

Rivets : Mainly used to connect thin-plate components, such as connecting the body and the chassis.

Clips : Used to connect some non-load-bearing components, such as securing wire harness fixtures.

As critical C-parts in automotive fastener supply chain, effective management is essential for optimizing overall supply chain efficiency. We understand the challenges buyers and engineers face in ensuring stable supply, reducing costs, and improving quality. By partnering with us, you can:

Streamline Procurement: We offer one-stop solutions, reducing supplier numbers and management costs.

Optimize Inventory Management: We provide VMI (Vendor Managed Inventory) and JIT (Just-In-Time) delivery services, ensuring timely supply and reducing inventory buildup.

Enhance Quality Control: We have an IATF 16949 certified production system, ensuring product quality meets the highest standards.

Build Long-Term Partnerships: We are committed to establishing long-term, stable partnerships with our customers, jointly addressing supply chain challenges and achieving mutual benefits.

As critical C-parts in automotive fastener supply chain, effective management is essential for optimizing overall supply chain efficiency. We understand the challenges buyers and engineers face in ensuring stable supply, reducing costs, and improving quality. By partnering with us, you can:

Streamline Procurement: We offer one-stop solutions, reducing supplier numbers and management costs.

Optimize Inventory Management: We provide VMI (Vendor Managed Inventory) and JIT (Just-In-Time) delivery services, ensuring timely supply and reducing inventory buildup.

Enhance Quality Control: We have an IATF 16949 certified production system, ensuring product quality meets the highest standards.

Build Long-Term Partnerships: We are committed to establishing long-term, stable partnerships with our customers, jointly addressing supply chain challenges and achieving mutual benefits.

We share daily update in our Insightful NEWSLETTER!

Learn more and Contact us

https://www.zjzrqc.com/contact/

Thanks in advance,

Zhejiang Zhongrui Auto Parts

Click Drop us a messageto get the latest catalog and quotation

Linkedin Page • Products • Meet us at exhibition • Drop us a message

And Get A Free Consultation!

English

English 中文简体

中文简体