Automotive Supply Chain Insights: Fastener Selection Guide for Electrical Systems of EVs

This article will focus on the critical fasteners in the electrical systems of EVs, providing an in-depth analysis of their functional requirements and offering specific selection guidance to help engineers.

Functional Analysis of Fasteners in Key Areas

Battery Pack Fixation Fasteners: As the core energy component of an EV, the battery pack must be fixed securely and reliably to withstand vibrations, impacts, and potential collisions during vehicle operation. Fasteners need to possess extremely high strength, excellent fatigue resistance, and superior corrosion protection to ensure the battery pack's safety under all operating conditions.

Motor/E-drive System Mounting Fasteners: The motor and e-drive system are the vehicle's power source, and their mounting fasteners must withstand the torque and vibrations generated during motor operation, ensuring stable power output. High strength and reliable anti-loosening performance are critical requirements for these fasteners.

Electronic Control Unit (ECU) Fixation Fasteners: The ECU is the "brain" of the EV, controlling various vehicle functions. Its fixation fasteners need to ensure stable operation of the ECU under vibration and impact environments. Good vibration resistance and reliable connection are crucial. Additionally, some ECUs may be sensitive to electromagnetic interference, requiring consideration of the fasteners' electromagnetic compatibility.

High-Voltage Wiring Harness Connection Fasteners: High-voltage wiring harnesses are critical for power transmission in EVs. Their connection fasteners need to ensure the reliability and safety of the harness connections, preventing short circuits or poor contact due to loosening. Reliable locking performance and good conductivity (for some grounding connections) are key.

Charging Port Fixation Fasteners: The charging port is the interface between the EV and external power sources. Its fixation fasteners need to withstand the stress from frequent plugging and unplugging operations and ensure the port's stability. Appropriate strength and wear resistance are factors to consider.

Specific Fastener Selection Guidance for Key EV Systems

Battery Pack Fixation: It is recommended to use high-strength alloy steel bolts (grade 10.9 or higher) with Dacromet or zinc-nickel alloy coating for excellent corrosion resistance. Additionally, it is essential to use high-reliability locking nuts or bolts with anti-loosening coatings to ensure the battery pack does not detach in the event of a vehicle collision.

Motor/E-drive System Mounting: Select high-strength alloy steel bolts (grade 10.9 or higher) and implement effective anti-loosening measures (such as locking nuts or thread-locking adhesives) to withstand the torque and vibrations generated during motor operation.

Electronic Control Unit (ECU) Fixation: Choose screws or bolts with good vibration resistance, and consider using products with elastic washers or anti-loosening threads. For ECUs with electromagnetic compatibility requirements, select non-conductive fasteners or those with specific shielding properties.

High-Voltage Wiring Harness Connection: It is recommended to use screws or bolts with locking features to ensure connection reliability. For grounding connection points, select fasteners with good electrical conductivity and ensure reliable contact.

Charging Port Fixation: Medium to high-strength carbon steel or alloy steel screws/bolts can be used, with appropriate surface treatment to enhance wear and corrosion resistance.

Key Fastener Properties (EV Electrical Systems)

Strength Grade: Definition: Bolt/stud tensile strength (e.g., 8.8, 10.9). Example: 8.8 grade: R m ≥ 800 MP a , R e l ≥ 640 MP a . Selection: High-stress (battery, motor): ≥10.9. General: Based on stress (e.g., 8.8).

Material: Common: Carbon steel, alloy steel, stainless steel (304, 316). Selection: High strength: Heat-treated alloy steel. Corrosion resistance: Stainless/treated carbon steel. Lightweight: Consider high-strength alloys.

Surface Treatment: Common: Zinc plating, hot-dip galvanizing, Dacromet, phosphating, black oxide. Selection: General rust: Zinc. High rust: Hot-dip/Dacromet (>500h salt spray). Severe corrosion: Stainless/special coatings. Note friction.

Anti-loosening: Common: Spring washers, locking nuts (nylon/metal), locking washers, threadlocker. Selection: General vibration: Spring washers. Med/high vibration (motor, battery): Locking nuts/threadlocker (check torque). Special: Mechanical washers. Refer to supplier data.

Dimensions & Specs: Definition: Thread (diameter, pitch), length, head, etc. Selection: Match space/load; ensure thread engagement. Follow standards.

Preload: Definition: Tightening axial force for joint reliability. Selection: Calculate based on importance, load, strength. Use torque wrenches. Refer to handbooks/standards.

As critical C-parts in the automotive fastener supply chain, effective management of ball studs is essential for optimizing overall supply chain efficiency. We understand the challenges buyers and engineers face in ensuring stable supply, reducing costs, and improving quality. By partnering with us, you can:

Streamline Procurement: We offer one-stop solutions, reducing supplier numbers and management costs.

Optimize Inventory Management: We provide VMI (Vendor Managed Inventory) and JIT (Just-In-Time) delivery services, ensuring timely supply and reducing inventory buildup.

Enhance Quality Control: We have an IATF 16949 certified production system, ensuring product quality meets the highest standards.

Build Long-Term Partnerships: We are committed to establishing long-term, stable partnerships with our customers, jointly addressing supply chain challenges and achieving mutual benefits.

We share daily update in our Insightful NEWSLETTER!

Learn more and Contact us

https://www.zjzrqc.com/contact/

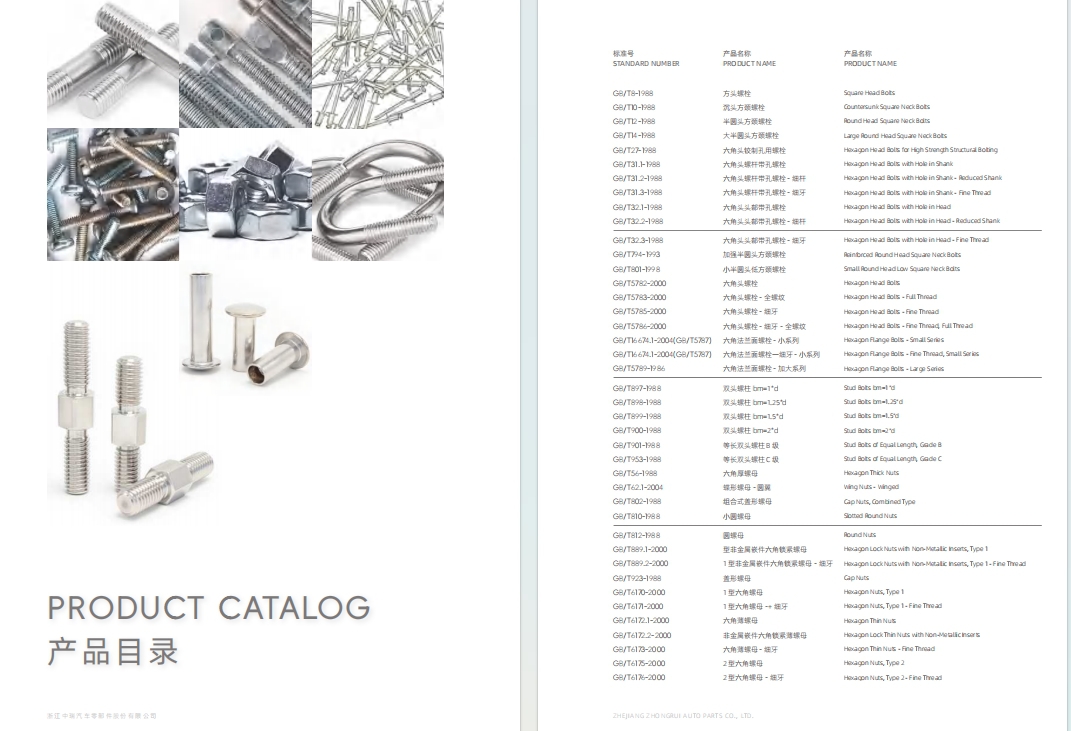

Zhejiang Zhongrui Auto Parts

Click Drop us a messageto get the latest catalog and quotation

And Get A Free Consultation!

English

English 中文简体

中文简体